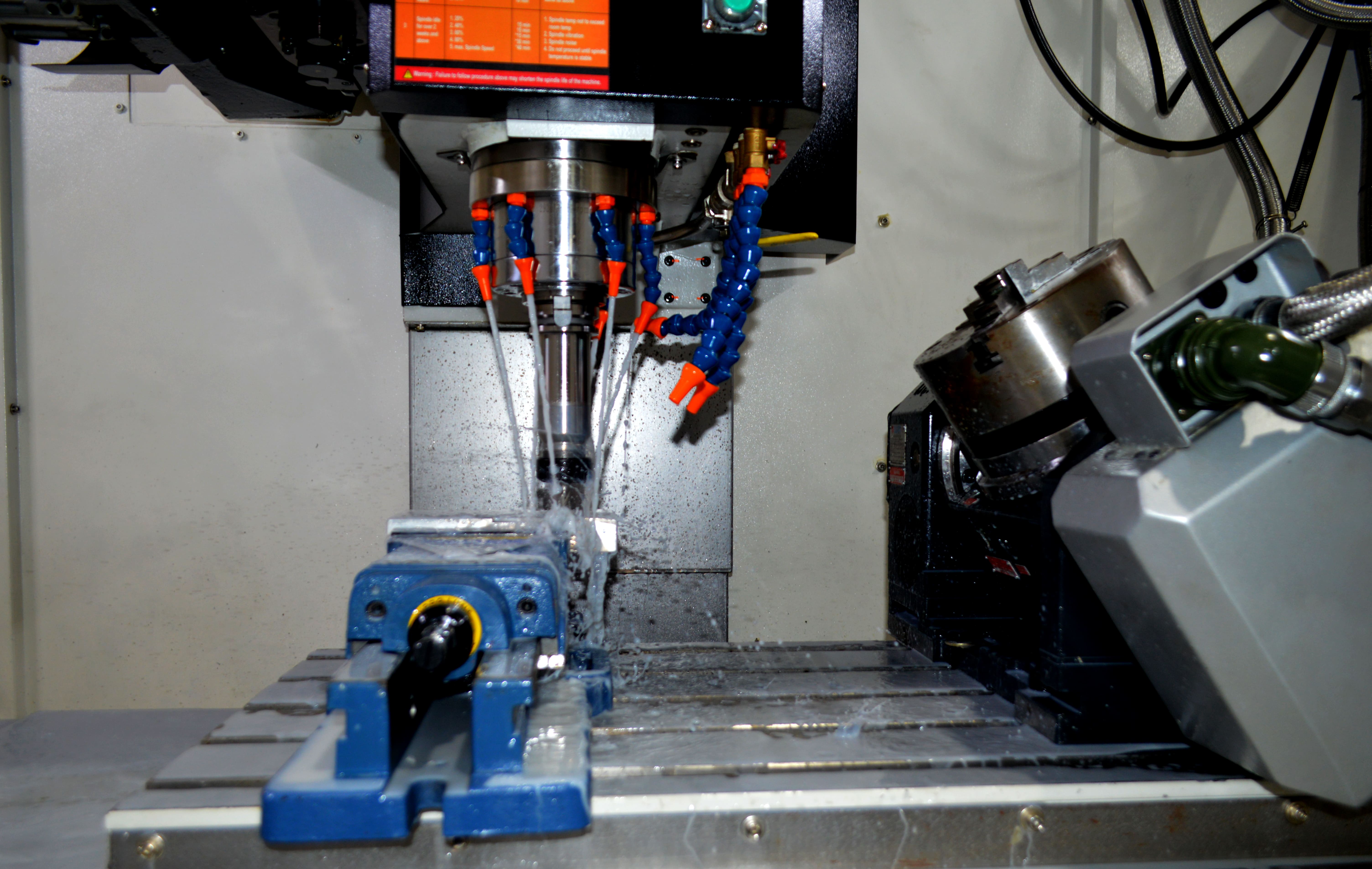

Lubrication could be critical in keeping cutting tools working totally. With HSS(High Speed Steel) cutting tools it is vital to place them lubricated when cutting metal materials.

Go for lifts created with CNC Machining and Delrin ball bearings. You have to have value for your own money, so make sure these lifts come with quality and precision.

There are a couple people who would do this editing line by line because the design is clear-cut. Now think of a posh shape exactly what scaling upward or down would include. This would include massive changes with it and reviewing it line by line. We are talking amount of lines here vs. moving back and quickly scaling is not and spitting out some new G-Code.

In the easiest of terms, think for this drill click. It’s a machine that drills holes. Just before you can drill the hole, you need to loosen the chuck, install the correct drill bit, drill the outlet in the correct place, turn off the drill, and collect drill small amount. Manually, this could be time-consuming and cause fatigue of the internet marketing of numerous parts. That is a simple example, but throw in some lathe or milling machining and you’ve got a greater chance for error.

The machining process operates on two different strands of mechanical workout. There is a primary motion functions between the relative motion that is generated with the machine as well as the tool. There is another motion that is basically the cutting speed. The secondary motion or the Feed practices these two. To bring about the truth that retreats into each of this designed products, each of the three motions has to operate out properly. Every kind of material you can think of- aluminum, steel, wood, iron, stone, can be cut by this turning center. There is a regarding tolerance using the machining on this machine and thus the supreme precision because of this generated.

Once somebody comes at the top of the idea to complete the computer mouse, he gets to be a preliminary product design made, then a mold making company is contracted to build the mold, a mold designer shows up with a “blueprint” (nobody uses blueprints anymore, is actually always called CAD because around the globe done on the computer), eventually the mouse gets molded into the plastic piece.

I have one of those “invisible jobs” that is seldom recognized, but universally valued. You see, everyone likes from other CNC Machining & Manufacturing cell phone, computer, driving their car, playing CD’s, and generally enjoying the fruit just about all our effort and hard work.

Every machine uses some type of tool. This is a router bit, a grinder, a driller, a stop mill, and many others. There could be several types of such specialist tools. Each comes with its own expenses. The tool can be a solid investment s huge car . last for some time time till it wears out.