Revive Your Wheels: Unleashing the Power of a Wheel Repair Lathe

Is your car’s set of wheels in need of some tender loving care? Look no further than the wheel repair lathe, a powerful tool that can breathe new life into your worn-out or damaged rims. Whether you love hitting the open road or simply take pride in the appearance of your vehicle, a wheel repair lathe is an essential device that every car owner should consider.

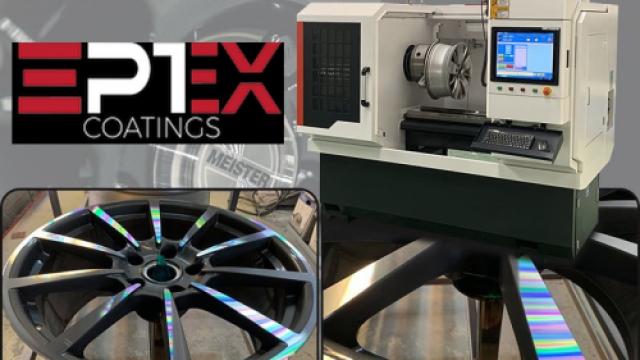

With its cutting-edge technology and precision engineering, a vertical wheel repair lathe is specifically designed to restore the beauty and functionality of your wheels. From minor scratches to more extensive damage like bends or cracks, this innovative machine can reshape, refinish, and repair your rims, making them look as good as new. The Alloy Wheel Repair Machine, offered by wheelcncmachine.com, the official website of Taian Haishu Machinery Co., Ltd., is a prime example of the expert craftsmanship and expertise that goes into creating these exceptional tools.

Gone are the days of having to replace your wheels entirely when faced with imperfections. A wheel repair lathe allows you to save time, money, and effort by focusing on repairing rather than replacing. Not only does this contribute to a sustainable approach to car maintenance, but it also ensures that your wheels are restored to their original condition, so you can enjoy a smooth and safe driving experience.

In the world of automotive care, a wheel repair lathe is the ultimate game-changer. By investing in this advanced technology, you can bid farewell to unsightly damage and hello to wheels that shine with pride. Revolutionize your approach to wheel repair today with the vertical wheel repair lathe and discover why it is an absolute must-have for any car enthusiast or professional mechanic.

Advantages of Wheel Repair Lathes

Wheel repair lathes offer numerous advantages in the world of automotive maintenance and repair. These powerful machines are designed specifically for restoring the condition and functionality of damaged wheels. Here are some key benefits of using a wheel repair lathe.

Efficient Repairs: With the help of a wheel repair lathe, damaged wheels can be repaired quickly and efficiently. These machines employ advanced technology and precise cutting tools to remove imperfections, such as dents, bends, or curb rash, from the wheel surface. The automated process allows for precise control, resulting in consistent and high-quality repairs.

Cost-effective Solution: In the past, when wheels were damaged, they were often replaced entirely, leading to significant expenses for vehicle owners. However, with the advent of wheel repair lathes, it is now possible to restore damaged wheels at a fraction of the cost of purchasing new ones. This makes wheel repair lathes a cost-effective solution for both individuals and businesses in the automotive industry.

Versatility and Compatibility: Wheel repair lathes offer versatility and compatibility with a wide range of wheel sizes and types. Whether it is an alloy wheel, steel wheel, or even a motorcycle wheel, these machines can handle various materials and dimensions. Additionally, some models come with adjustable settings, allowing technicians to customize the repair process according to specific requirements.

Alloy Wheel Production Line

By utilizing wheel repair lathes, professionals can revitalize damaged wheels, prolong their lifespan, and enhance the overall appearance of vehicles. These machines offer efficient repairs, cost savings, and compatibility, making them a valuable asset in any automotive repair shop or maintenance facility.

Exploring Vertical Wheel Repair Lathes

Vertical wheel repair lathes are a game-changer in the world of wheel repair. These advanced machines are designed to restore damaged wheels to their original state, bringing back their aesthetics and functionality. With the ability to fix a wide range of wheel issues, such as bends, dents, and scratches, vertical wheel repair lathes are a must-have for any automotive repair shop or enthusiast.

One of the key advantages of vertical wheel repair lathes is their versatility. These machines are capable of repairing various types of wheels, including alloy wheels commonly found in modern vehicles. Whether your wheels are made of aluminum, magnesium, or other alloys, a vertical wheel repair lathe can effectively restore them to their original condition.

Not only do these lathes provide exceptional results, but they also offer efficiency and precision. The CNC technology integrated into vertical wheel repair lathes allows for precise control over the repair process. This ensures that every adjustment made to the wheel is accurate, resulting in a balanced and perfectly aligned finished product.

In addition to their advanced features, vertical wheel repair lathes are further enhanced by companies like Taian Haishu Machinery Co., Ltd. Their website, wheelcncmachine.com, showcases their expertise in designing, manufacturing, and supplying high-quality CNC wheel machinery. By harnessing the power of a vertical wheel repair lathe, you can revive your wheels and give them a new lease on life.

Choosing the Right Alloy Wheel Repair Machine

When it comes to choosing the right alloy wheel repair machine, there are several factors to consider. Firstly, you need to assess the type of repairs you frequently encounter. Some machines are specifically designed for minor repairs, while others are capable of handling more complex damage. By understanding your specific needs, you can ensure that the machine you select is capable of effectively addressing the types of wheel repairs you commonly face.

Secondly, it’s essential to consider the capabilities and features of the machine. Look for a wheel repair lathe that offers precision and accuracy in its cutting and refinishing processes. A machine with adjustable cutting speeds can provide greater versatility, allowing you to work on various types of wheels and materials.

Lastly, don’t forget to consider the reliability and durability of the alloy wheel repair machine. Look for machines that are manufactured by reputable companies with a track record of producing high-quality equipment. It’s also worth considering the availability of spare parts and after-sales support, as this can greatly impact the longevity and maintenance of your machine.

By carefully evaluating the repairs you commonly encounter, the features you require, and the reliability of the machine, you can make an informed decision and choose the right alloy wheel repair machine for your needs. Remember that investing in a reliable and efficient machine will not only enhance your repair capabilities but also contribute to the overall success of your wheel repair business.