In the world of industrial processes, the precision and reliability of valves and controls play a vital role in ensuring smooth operations and optimal performance. Valves serve as the essential gatekeepers, regulating the flow of liquids, gases, and other substances within intricate systems. Coupled with advanced controls, these mechanisms become the backbone of various sectors, from manufacturing plants to government facilities, providing efficiency and safety.

Valworx stands out as a reputable player in this landscape, offering a comprehensive range of actuated valves and controls that adhere to the stringent standards of ISO 9001 certification. With a commitment to quality and expedited service, Valworx swiftly assembles and tests hundreds of automated valve solutions, ready for same-day delivery to our valued clientele in the industrial, institutional, and government sectors.

Valve Types and Applications

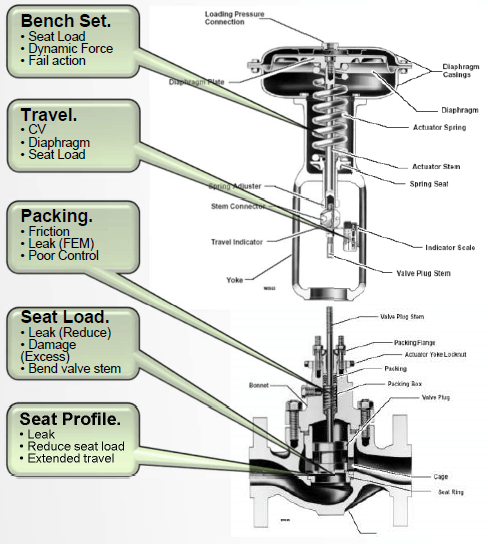

When it comes to valves and controls, understanding the different types of valves available and their applications is essential for mastering the art of valve control. Valves play a crucial role in regulating the flow of fluids or gases within a system, and selecting the right type of valve is key to ensuring optimal performance.

One common type of valve is the ball valve, known for its simple design and versatility. Ball valves are often used in applications where tight shut-off is required, making them ideal for use in various industries such as oil and gas, chemical, and water treatment. Another popular valve type is the butterfly valve, which offers a lightweight and compact design suitable for large flow applications.

Lug style butterfly valve for HVAC systems

For more complex control requirements, globe valves are preferred due to their precise flow control capabilities. Globe valves are commonly used in systems where throttling or regulating flow is necessary, such as in HVAC systems and power plants. Understanding the unique characteristics and applications of these valve types is key to effectively managing fluid flow within industrial, institutional, and government environments.

Benefits of Actuated Valves

Automated valves offer increased efficiency in various industries by allowing for precise control of flow rates and pressure levels, enhancing overall system performance. Valworx’s actuated valves are engineered to streamline operations, minimizing downtime and maximizing productivity for our customers. With quick response times and reliable performance, these valves contribute to operational cost savings over time.

The integration of actuated valves provides enhanced safety measures by reducing the need for manual intervention in critical processes. Valworx’s ISO 9001-certified actuated valves ensure consistent and accurate control, minimizing the risk of human error and potential hazards in industrial settings. By automating valve functions, operators can maintain a safe working environment and mitigate potential accidents or equipment damage.

Valworx’s actuated valves offer seamless compatibility with various control systems, enabling easy integration and flexible operation across different applications. This adaptability allows for customization according to specific requirements, enhancing system versatility and scalability. By choosing Valworx’s reliable actuated valves, industries can achieve optimal performance and operational efficiency in their processes.

Selecting the Right Valve for Your Application

When it comes to selecting the right valve for your specific application, it is crucial to consider factors such as the type of fluid being controlled, the operating pressure and temperature, as well as the flow rate requirements. Valworx understands the importance of these considerations and offers a wide range of automated valve assemblies to suit various needs.

One key aspect to keep in mind is the material of the valve body and components. Different materials have varying resistance to corrosion, abrasion, and other harsh conditions. Valworx’s valves are constructed using high-quality materials to ensure durability and longevity in diverse environments, providing reliability and efficiency in valve control systems.

In addition to material considerations, understanding the type of control needed is essential. Whether it’s on-off, modulating, or proportional control, Valworx provides expertly engineered valve solutions that cater to different control requirements. By selecting the right valve type based on the control needed, users can optimize performance and enhance the overall functionality of their systems.