As we step into the future, the landscape of heavy vehicle manufacturing and supply is undergoing a profound transformation. The realm of large-scale transportation is poised for revolution, driven by technological advancements, sustainability initiatives, and evolving consumer demands. Companies within this sector are reimagining traditional practices, adopting innovative approaches, and redefining the very essence of what it means to design, produce, and distribute heavy vehicles. This paradigm shift is not just about reengineering the physical aspects of these mammoth machines but also about reshaping the entire ecosystem in which they exist. The future holds a promise of efficiency, sustainability, and unparalleled connectivity across the heavy vehicle manufacturing and supply chain.

Challenges in Heavy Vehicle Manufacturing

One of the primary challenges in heavy vehicle manufacturing is the increasing demand for vehicles that are more fuel-efficient and eco-friendly. Manufacturers are constantly under pressure to improve the fuel efficiency of their vehicles while also reducing emissions to comply with stricter environmental regulations.

Another significant challenge is the complexity of supply chain management in heavy vehicle manufacturing. Coordinating the production of various components from multiple suppliers can lead to delays and logistical issues. Ensuring the timely delivery of parts while maintaining quality control standards is a constant struggle for manufacturers.

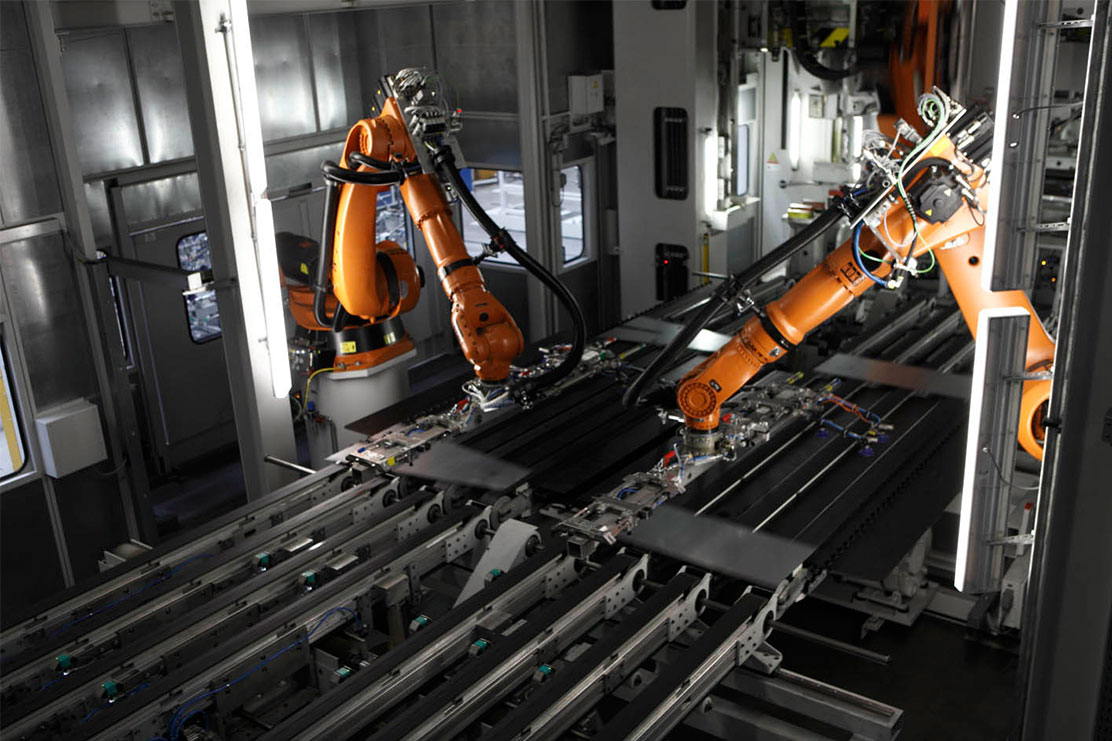

Furthermore, technological advancements pose a challenge in heavy vehicle manufacturing as companies must stay abreast of the latest innovations to remain competitive. Implementing new technologies such as automation, artificial intelligence, and data analytics requires significant investment and skilled personnel, adding another layer of complexity to the manufacturing process.

Technological Innovations in the Industry

In recent years, heavy vehicle manufacturing has witnessed a surge in technological advancements. Automation systems have revolutionized production processes, leading to increased efficiency and precision in the assembly of heavy vehicles.

Quality semi trailers from trusted manufacturers

The integration of artificial intelligence and machine learning algorithms has played a crucial role in optimizing supply chain management within the heavy vehicle manufacturing industry. Predictive analytics tools now enable manufacturers to anticipate demand, streamline logistics, and minimize disruptions in the supply chain.

Furthermore, the adoption of Internet of Things (IoT) technology has paved the way for enhanced connectivity and real-time data monitoring in heavy vehicle manufacturing. IoT sensors embedded in vehicles allow for remote diagnostics, predictive maintenance, and improved overall performance, contributing to a more sustainable and reliable supply chain ecosystem.

Sustainable Supply Chain Practices

One key aspect of revolutionizing heavy vehicle manufacturing and supply is the implementation of sustainable supply chain practices. This involves adopting environmentally friendly methods in sourcing raw materials, manufacturing processes, and transportation logistics. By incorporating sustainable practices, such as using renewable energy sources and reducing waste, heavy vehicle manufacturers can minimize their carbon footprint and contribute to a greener future.

In addition to environmental considerations, sustainable supply chain practices also focus on social responsibility. This includes ensuring fair labor practices, promoting diversity and inclusion in the workforce, and supporting local communities where manufacturing facilities are located. By prioritizing social responsibility, heavy vehicle manufacturers can create a positive impact beyond their products, fostering goodwill among stakeholders and enhancing their brand reputation.

Moreover, implementing sustainable supply chain practices can result in cost savings and operational efficiencies for heavy vehicle manufacturers. By optimizing processes, reducing energy consumption, and streamlining transportation routes, companies can lower their overall production costs and improve their bottom line. In the long run, embracing sustainability in supply chain management is not only beneficial for the environment and society but also for the overall business sustainability of heavy vehicle manufacturers.