In the world of manufacturing, the transformation of raw materials into finished products is a fascinating journey that combines innovation, precision, and craftsmanship. One such remarkable transformation takes place in the realm of brush machine components, where companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are at the forefront of this industry. With an impressive 37 years of experience, this professional company has honed its expertise in producing state-of-the-art 2-5 axis machines, designed to meet the ever-evolving needs of brush production.

The journey of these components begins with the careful selection of raw materials and continues through a series of intricate processes that convert them into high-quality machines. Jiangmen Meixin Comb not only focuses on the technical aspects of manufacturing but also embraces the art of innovation, ensuring that each machine reflects a commitment to excellence and durability. As customers increasingly demand efficiency and reliability, the evolution of brush machine technology remains a pivotal factor in pushing the boundaries of what is possible in manufacturing.

Overview of Jiangmen Meixin Comb

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands out as a leader in the brush machine industry, dedicating itself to the art of transforming raw materials into high-quality brush components. With a rich history spanning 37 years, the company has cultivated a wealth of expertise in designing and producing advanced machinery that caters to various brush-making needs. Their specialization in 2-5 axis machines ensures that clients have access to cutting-edge technology that enhances productivity and precision in the manufacturing process.

The commitment to quality and innovation is evident in the company’s approach to production. Jiangmen Meixin Comb integrates modern techniques with traditional craftsmanship, ensuring that their machines are not only efficient but also durable. This blend of experience and continual development has established the company as a trusted partner for businesses looking to enhance their brush-making operations. The team’s technical accumulation over the years has honed their skills, allowing them to adapt to the evolving demands of the market.

In addition to manufacturing, Jiangmen Meixin Comb places a strong emphasis on customer satisfaction. By offering comprehensive support and tailored solutions, they help clients navigate the complexities of brush production. The company’s reputation is built on reliable service and a commitment to helping businesses succeed, making them a preferred choice in the industry. Their extensive knowledge and dedication ensure that they are well-equipped to meet the challenges of today’s dynamic manufacturing landscape.

Technological Innovations in Brush Machines

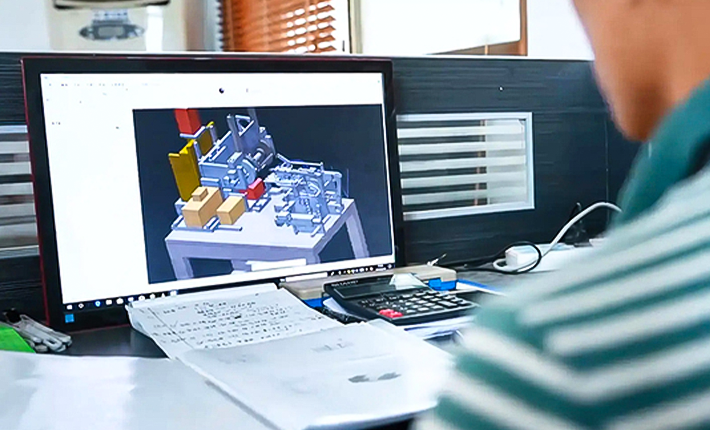

In recent years, the brush machine industry has seen significant advancements driven by technological innovations. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. have been at the forefront of this evolution. With 37 years of production experience, they have integrated cutting-edge technologies into their 2-5 axis machines, enhancing precision and efficiency in brush manufacturing. These innovations not only streamline the production process but also improve the quality and consistency of the finished products.

The introduction of automation and robotics has revolutionized brush machine operations. Automated systems allow for faster production cycles while minimizing human error. Jiangmen Meixin has embraced this trend, incorporating smart technologies that analyze production data in real-time, leading to better decision-making and reduced downtime. The seamless integration of these technologies ensures that manufacturers can meet increasing market demands without compromising on quality.

Furthermore, technological advancements in materials science have greatly impacted brush machine efficiency. The development of new, durable materials has enabled machines to produce more resilient brushes that withstand aggressive use and environmental factors. Jiangmen Meixin’s commitment to research and development ensures they remain competitive by adopting these advancements, ultimately resulting in innovative products that cater to diverse customer needs in various industries.

Production Processes and Techniques

At Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., the production of brush machine components involves a series of precise and sophisticated processes. Each machine is designed with advanced technology, allowing for the fabrication of high-quality components tailored to meet diverse customer needs. The manufacturing journey begins with the selection of raw materials, which are sourced for their durability and compatibility with various brush types. This careful selection ensures that the end products are resilient and long-lasting. In the realm of manufacturing, companies like Jiangmen Meixin Com are revolutionizing production processes with their innovative designs, including the Brush Machine for Large Scale Production which enhances efficiency and quality in creating brush components.

Once the materials are in place, the production process employs both automated and manual techniques to shape and assemble the components. The use of 2-5 axis machines allows for intricate designs and precise cuts, making it possible to craft complex brush shapes that would be difficult to achieve with traditional methods. Skilled technicians oversee these operations, ensuring that each piece meets the company’s high standards of quality and performance. With 37 years of experience, the team expertly combines modern technology with time-honored techniques to deliver exceptional results.

Quality control is a critical aspect of the production processes at Jiangmen Meixin. Each component undergoes rigorous testing to ensure it meets specific performance criteria before it is integrated into the final machines. Continuous improvement and technical accumulation over the years have positioned the company as a leader in the brush machine manufacturing industry. This commitment to excellence not only enhances the reliability of their products but also builds trust with customers worldwide.

Quality Control and Assurance

Quality control is a fundamental aspect of the manufacturing process at Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With 37 years of production experience, the company has developed robust quality assurance protocols to ensure that every brush machine component meets the highest standards. The implementation of strict inspection procedures at various stages of production guarantees that raw materials and finished products are thoroughly evaluated before they reach the customer.

Throughout the manufacturing journey, skilled technicians conduct detailed assessments of the components. These assessments include dimensional checks, material analysis, and operational testing to verify the machines’ performance. By leveraging advanced technology and their wealth of experience, Jiangmen Meixin ensures that any potential defects are identified and addressed in a timely manner, minimizing the risk of issues for end-users.

In addition to in-house quality control, Jiangmen Meixin values feedback from clients to continually refine their products. This customer-centric approach not only enhances their manufacturing processes but also fosters long-term relationships based on trust and reliability. By prioritizing quality assurance, the company maintains its reputation as a leader in the brush machine manufacturing industry.

Future Trends in Brush Manufacturing

The brush manufacturing industry is poised for significant advancements as technology continues to evolve. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are at the forefront of this transformation, leveraging their 37 years of expertise in developing innovative 2-5 axis machines. These machines are designed to enhance precision and efficiency in production processes, allowing manufacturers to create more complex and customizable brush components that meet diverse consumer demands.

Sustainability will also play a crucial role in the future of brush manufacturing. As environmental awareness grows, manufacturers are increasingly looking for ways to reduce waste and utilize eco-friendly materials in their products. This shift towards sustainable practices not only helps in minimizing environmental impact but also attracts a more conscientious consumer base. Jiangmen Meixin is already exploring ways to integrate sustainable raw materials and energy-efficient technologies in their production lines.

Finally, the rise of automation and smart manufacturing will redefine operational efficiency in the industry. Automated systems and artificial intelligence can optimize production workflows, reduce labor costs, and improve product quality. As the industry embraces these technologies, companies that adapt quickly will have a competitive edge. Jiangmen Meixin is already capitalizing on these trends, ensuring that they remain a leader in brush machine manufacturing for years to come.